Case Model predictive control of phenolic resin production

Cybernetica delivers Model Predictive Control (MPC) and Endpoint Prediction of phenolic resin manufacturing processes based on Cybernetica CENIT. This system is currently controlling numerous resole phenolic resin reactors in North America, Oceania and Europe.

MPC is used for control of reactor temperature and reaction rates, by controlling cooling and heating utilities and metering (dosing) rates of formaldehyde, phenol and catalysts.

The main benefits of using this technology compared to conventional control are:

- Stable, accurate and consistent control of reactor temperature and reaction rates.

- Shorter and less variations in batch cycle times.

- Improved consistency of product quality parameters.

- Improved safety.

- Endpoint (cut-off) determination using kinetic model.

- Less need to take grab samples from the reactor.

- Less operator intervention – higher degree of automation.

The essential features of the Cybernetica CENIT, which enable these benefits, are:

- Online parameter estimation – the model adapts online to changes in process conditions.

- Predictive control – the future process performance is continuously predicted and optimized.

Process modelling

The mechanistic process model utilized within Cybernetica CENIT is adapted to each specific process unit. Reactor design data are acquired from the customer. Other model parameters are estimated off-line from logged process data using Cybernetica ModelFit.

Model of phenolic resin reactor

- Kinetics and thermodynamics:

- Methylolation reactions

- Condensation reactions

- Formaldehyde, hemiformal and ionization equilibria

- Cooling and heating utilities:

- Coil cooling is dependent on estimated heat transfer coefficients and on the liquid level in the reactor.

- Reflux condenser and vacuum system.

- Steam heating.

- Feed systems for raw materials

Model predictive control (MPC)

MPC enables safe and accurate control of reaction rate and reactor temperature by controlling:

- Coil cooling, jacket cooling and steam heating.

- Vacuum and condenser cooling during polymerization and distillation.

- Metering (dosing) rates of formaldehyde, phenol and catalysts.

MPC allows fast response to step changes in temperature setpoints, which will reduce batch cycle times. Predictive temperature control is illustrated in the video below.

Temperature control during initial exotherm and step change of temperature setpoint. The predicted cooling water flow and reactor temperature, during the 15 minutes prediction horizon, are shown to the right of the vertical line indicating present time. A 15 minutes history is shown to the left.

Safe and efficient metering of raw materials

The metering (dosing) rates of raw materials are safely controlled such that the predicted reaction heat does not exceed the currently available cooling capacity, and such that other constraints (e.g., maximum reactor temperature rate of change) are not violated. The available cooling capacity may typically vary significantly during a batch due to

- changes in cooling water temperatures,

- changes in available cooling water flow rates,

- varying heat transfer coefficients,

- and varying liquid level in the reactor.

All these changes are immediately compensated for in the calculation of raw material metering rates.

Optimal metering rates of formaldehyde will typically vary greatly from start to end of the metering phase, and there is a lot to gain in batch cycle time, in addition to the safer operation, by utilizing MPC.

Safe operation

Cybernetica CENIT ensures that the polymerization reactions are safely controlled in spite of uncertain and rapidly changing cooling capacity. The adaptive model will also compensate for deviations between the reaction heat predicted by the model and the actual reaction heat observed from reactor measurements.

In addition to the inherent safety associated with the model predictive control methodology and the online model adaptation, CENIT includes functionality for fault detection and diagnosis.

Automatic endpoint determination

Endpoint determination of “shortly condensed” resins of low viscosity development are often accomplished by manually analysing grab samples from the reactor, e.g. for free phenol content or based on cloud point determination. This is undesirable when full automation is aimed for.

The degree of polymerization, as calculated from the kinetic model, is successfully being used for endpoint determination of shortly condensed resins, resulting in improved consistency of product quality parameters.

Operator graphic for polymerization monitoring

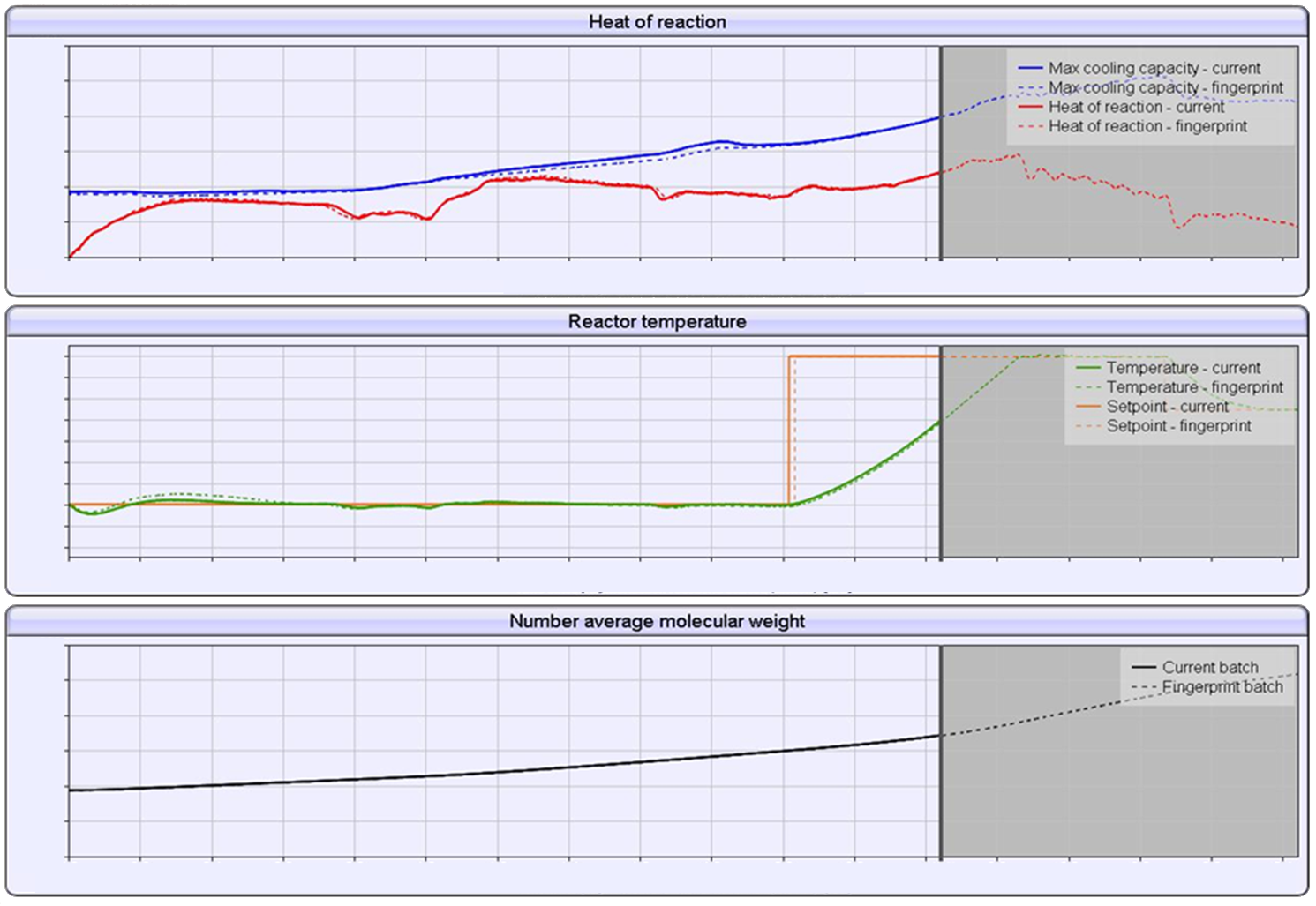

The system includes an operator graphic display where temperature, reaction heat and cooling capacity profiles are compared to those of a previously manufactured “golden batch”. The “golden batch” profile is “time warped” to make the two batches comparable even though the reaction rates progress differently with time. The purpose of the polymerization monitoring system is to:

- Monitor the development of the current batch, as compared to the golden batch.

- Detect deviations between the current batch and the golden batch.

- Predict the future progress of the current batch, including the endpoints.

A snapshot of the graphic display is shown in the figure below. The history is displayed to the left of the vertical line indicating present time, and the future predictions are shown to the right. The graphic display is used to monitor the current batch (solid lines) by comparing with a previously manufactured “golden batch” (dashed lines). The reaction heat and the maximum cooling capacity are shown in the upper graph; the reactor temperature and the temperature setpoint are shown in the middle graph. A selection of user defined variables can be shown in the lower graph.

Implementation

Cybernetica CENIT applications typically runs on a dedicated application station (Windows server). It communicates with a DCS system via the Open Platform Communications (OPC) protocol.

Cybernetica employees have extensive experience in industrial implementation and commissioning of advanced process control (APC) applications.

Integration with sequential batch control system

Cybernetica CENIT can run independently of a batch control system, with the operator providing essential inputs such as temperature setpoint profiles and raw material amounts. CENIT can, however, preferably be integrated with a sequential batch control system, in which case the batch control system will provide a number of input parameters to CENIT, dependent on the current stage in the batch process and on the specific resin grade being manufactured.

Maintenance

Cybernetica’s maintenance programme ensures that all applications perform at their best at all times. Cybernetica rapidly responds to customer requests. Cybernetica CENIT has built-in functionality for reproduction and diagnosis of current or past process situations, facilitating efficient analyses of issues reported by the customer.

The most common and important issues are reported directly to the operators, enabling the operators to act when necessary.