Case Optimization and model predictive control of PVC production

Cybernetica delivers systems for Run-to-run Optimization and Model Predictive Control (MPC) of PVC manufacturing processes based on Cybernetica CENIT.

The system optimizes temperature profile and dosing of initiators, with the purpose of minimizing polymerization time while meeting target quality specifications and fulfilling a number of process constraints. MPC is used for accurate temperature control in accordance with the optimized profile, by controlling heating and cooling utilities, and process water temperature.

The main benefits of using this technology compared to conventional control are:

- Increased productivity through optimization of temperature profile and initiator dosing, and accurate control in accordance with the optimized profile. The cooling capacity can usually be utilized close to its maximum during the entire polymerization phase.

- Accurate control of quality parameters (e.g., “K-number”) in accordance with target specifications.

- Condenser cooling capacity is maximized by controlling the venting of inert gases from the condenser, with minimum loss of VCM gas through the venting system.

- The MPC detects any drop in cooling capacity and, if necessary, determines the required amount of inhibitor before any significant temperature deviation has occurred.

Process modelling

The mechanistic process model utilized within Cybernetica CENIT is adapted to each specific process unit. Reactor design data are acquired from the customer. Other model parameters are estimated off-line from logged process data using Cybernetica ModelFit.

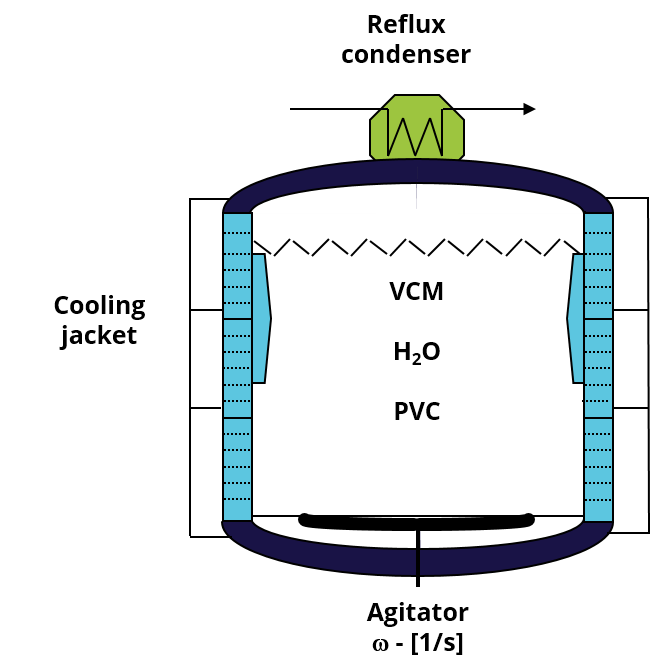

Model of suspension PVC polymerization autoclave

- Energy balances for suspension, cooling jacket and reflux condenser.

- Reaction kinetics:

- Free radical polymerization mechanism

- Thermodynamic calculations:

- Phase equilibria: Distribution of monomer between the four phases.

- Reactor pressure.

- Quality model:

- Quality parameters (e.g., Mn, Mw) are estimated from moments of the MWD and correlated to viscosity (“K-number”).

Estimation of model parameter profiles

Accurate prediction of cooling capacity and reaction heat is ensured as follows:

- Heat transfer coefficients for cooling utilities are estimated as conversion dependent parameter profiles, to account for the changes in these parameters during the progress of a single batch. The estimated parameter profiles are also continuously updated to account for drift in heat transfer capabilities over a longer time scale.

- Any deviation between the reaction heat predicted by the kinetic model and the reaction heat observed from process measurements are compensated for by the estimation of conversion dependent corrections to the kinetic model.

Run-to-run optimization

The temperature profile and the quantities of initiators are optimized at the start of each batch:

- The optimization is based on an economic criterion, weighting cost of batch time versus cost of each available initiator.

- The optimization is performed such that the target product quality and a number of safety related and other process constraints are fulfilled.

Model predictive control (MPC)

MPC enables accurate control in accordance with the optimized batch profile:

- The initial polymerization temperature is reached fast and energy efficient by controlling the temperature of process water during the reactor charging phase.

- The MPC controls the flow rates of cooling water to the jacket and condenser cooling systems, and distributes the available cooling water between the cooling utilities in an optimal way.

- Venting of inert gases from the condenser is controlled based on the profile of the estimated condenser heat transfer coefficient, with the purpose of maximizing cooling capacity while minimizing loss of VCM gas through the venting system.

- The MPC predicts if the heat of reaction will exceed the available cooling capacity, and determines the necessary amount of inhibitor to regain control of the polymerization temperature. This might occur due to an unexpected drop in cooling capacity, e.g. due to foaming.

Safe operation

The batch optimization will ensure that the predicted reaction heat does not exceed the calculated cooling capacity profile. Still, the cooling capacity might change during the batch due to changes in inlet cooling water temperature or other unexpected changes. However, the MPC controller will detect early in case the cooling capacity is not sufficient to control the temperature in accordance with the temperature reference profile, and the operators will be advised to charge a small amount of inhibitor in this situation, before the loss of cooling capacity has resulted in any significant deviation from the temperature reference trajectory.

In addition to the inherent safety associated with the MPC methodology and the online model adaptation, the CENIT system includes fault detection and diagnosis functionality.

Implementation

Cybernetica CENIT applications typically run on a dedicated application station (Windows server). It communicates with a DCS system via the Open Platform Communications (OPC) protocol.

Cybernetica employees have extensive experience in industrial implementation and commissioning of advanced process control (APC) applications.

Integration with sequential batch control system

Cybernetica CENIT can run independently of a batch control system, with the operator providing essential inputs. CENIT can, however, preferably be integrated with a sequential batch control system, in which case the batch control system will provide a number of input parameters to CENIT, dependent on the current stage in the batch process and on the specific PVC grade being manufactured.

Maintenance

Cybernetica’s maintenance programme ensures that all applications perform at their best at all times. Cybernetica rapidly responds to customer requests. Cybernetica CENIT has built-in functionality for reproduction and diagnosis of current or past process situations, facilitating efficient analyses of issues reported by the customer.

The most common and important issues are reported directly to the operators, enabling the operators to act when necessary.